تحول عملية تصنيع ملابس السباحة المخصصة أفكارك إلى ملابس سباحة حقيقية. يبدأ بالتصميم والبحث. ثم تذهب من خلال أخذ العينات والإنتاج. الخطوة الأخيرة هي الاستعداد للبيع. كان سوق ملابس السباحة العالمي يستحق23.1 مليار دولار أمريكي في 2023. ينمو بسرعة بسبب الاتجاهات والتكنولوجيا الجديدة. ملابس سباحة تيديلينيساعدك معحد أدنى مرن وعينات سريعة. كما أنها توفر التخصيص الكامل. هذا يجعل من السهل بدء متجر ملابس سباحة عبر الإنترنت أو علامة تجارية لملابس السباحة. يمكنك تجنب المشاكل من خلال التركيز علىالجودة والتواصل الواضح. يجب عليك أيضًا الحفاظ على الجداول الزمنية الفعالة أثناء العملية.

نصيحة: اختبار العينات مبكرًا والتحقق من التفاصيل للتأكد من أن ملابس السباحة المخصصة هي ما تريده.

الوجبات السريعة الرئيسية

ابدأ بفكرة واضحة لعلامتك التجارية ودراسة السوق. هذا يساعدك على جعل ملابس السباحة التي هي خاصة وتناسب المشترين الخاص بك. استخدام الرسومات التفصيلية والحزم التقنية لمساعدة الشركات المصنعة. هذا يمكن أن يمنع الأخطاء من الحدوث عند صنع ملابس السباحة الخاصة بك. اختيارمواد عالية الجودة وصديقو-التي لديها شهادات. هذا يبني الثقة ويساعد على حماية الأرض. العمل مع الشركات المصنعة التي تتيح لك طلب كميات مختلفة ، وإرسال عينات بسرعة ، والتحدث جيدًا معك. هذا يساعدك على إطلاق ملابس السباحة الخاصة بك بشكل أسرع. اختبار وتغيير العينات بعناية. هذا يضمن أن ملابس السباحة الخاصة بك تناسب بشكل جيد ، وتشعر بالرضا ، وجودة عالية قبل أن تصنع الكثير.

مفهوم وبحوث

رؤية العلامة التجارية

تحتاج إلى معرفة رؤية علامتك التجارية قبل أنبدء. فكر في سبب رغبتك في صنع ملابس السباحة وما يجعل علامتك التجارية مختلفة. هذا يساعدكحدد الأهداف وتبرزمن الآخرين. إليك بعض الخطوات لمساعدتك:

معرفة هوية علامتك التجارية وما تريد القيام به.

انظر إلى سوق ملابس السباحة للعثور على جمهورك والمنافسين الرئيسيين.

حدد ما يجعل علامتك التجارية مميزة. ربما تستخدم مواد بيئة-أو تقدم العديد من الأحجام.

وضع خطة عمل تغطي المال والأسعار والإعلانات والنمو.

اختر مواد جيدة وخطط لتدوم علامتك التجارية.

استخدم الإعلانات عبر الإنترنت واعمل مع المؤثرين لمساعدة علامتك التجارية على النمو.

تأكد من أن رؤيتك واضحة ويمكن أن تتغير مع السوق.

ملابس سباحة TideLine تساعدك في كل خطوة. أنها تعطي الدعم مع هوية العلامة التجارية ، والبحوث ، وصنع مرنة. هذا يساعد العلامات التجارية الجديدة والقديمة على الانضمام إلى سوق ملابس السباحة.

اتجاهات السوق

سوق ملابس السباحة يتغير بسرعة. تحتاج إلى مشاهدة الاتجاهات للحفاظ على ملابس السباحة الخاصة بك جديدة وشائعة. بعض الاتجاهات الكبيرة الآن هي:

ملابس سباحة مصنوعة من مواد معاد تدويرهامثل الربيت والألياف الطبيعية.

ميزات مثل مقاومة الكلور ، وأبف 50 + سلامة الشمس ، والأقمشة سريعة الجفاف.

العديد من الأحجام وملابس السباحة التكيفية لجميع أنواع الجسم.

البيع مباشرة للمشترين عبر الإنترنت وعلى وسائل التواصل الاجتماعي.

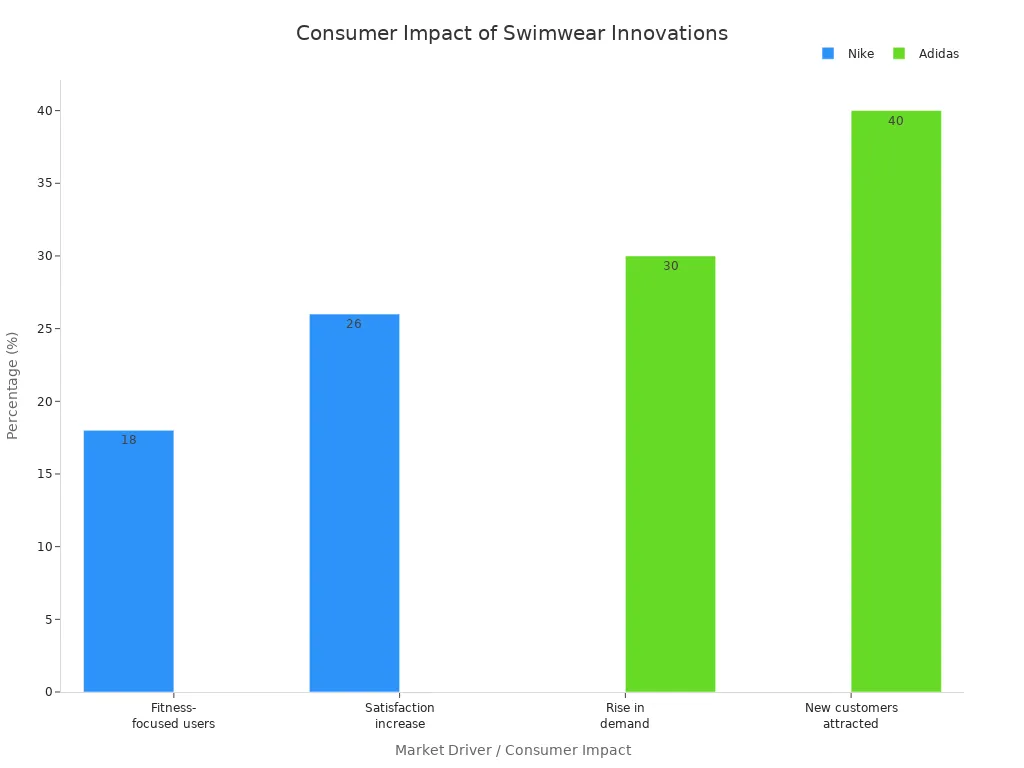

ملابس سباحة تيديلينملابس سباحة للرجالوملابس سباحة مستدامةأظهر كيف تتبع العلامات التجارية هذه الاتجاهات. على سبيل المثال ، استخدام الأقمشة المعاد تدويرها والمزيد من الأحجام يلبي ما يريده المشترون. الـالرسم البيانييوضح أدناه كيفية استخدام Nike و Adidas للأفكار الجديدة للحصول على المزيد من العملاء وجعلهم سعداء:

رؤى الجمهور

معرفة جمهورك يساعدك على صنع ملابس السباحة التي تبيع. انظر إلى هذه الأشياء:

جنس

الدخل

حيث يعيشون

مرحلة الحياة (مثل الطلاب أو الآباء)

الوظيفة

مستوى المدرسة

الحالة العائلية

يجب عليك أيضًا التعرف على نمط حياة جمهورك وما يريدونه في ملابس السباحة. بعض الناس يريدون ملابس السباحة الصديقّة. يريد الآخرون ميزات عالية الأداء. ملابس سباحة TideLine تساعدك على تعلم هذه الاحتياجات وتعطيكخيارات مرنةلملابس السباحة المخصصة. بهذه الطريقة ، يمكنك صنع منتجات تناسب جمهورك وتبرز في سوق ملابس السباحة.

عملية التصميم

رسومات وأفكار

تبدأ برسم أفكار ملابس السباحة الخاصة بك على الورق. تساعد الرسومات الجيدة الآخرين على معرفة ما تريد القيام به. استخدام أشكال الجسم الصحيحوممارسة رسم الناس في أوضاع مختلفة. ابدأ بمخطط خفيف للجسم. ثم ، رسم ملابس السباحة أكثر من ذلك. انتبه إلى الأشياء الصغيرة مثل الأشرطة وخطوط العنق وفتحات الساق. جرب العديد من الأنماط ، مثل البيكينيات أو قطعة واحدة أو جذوع الرجال. إضافة الألوان والقوام لإظهار ما سيبدو عليه النسيج. استخدم الملاحظات ولوحات المزاج لشرح اختياراتك. ملابس سباحة تيديلينخبراء التصميممن يمكنه مساعدتك في تحويل رسوماتك إلى ملابس سباحة حقيقية.

نصيحة: حاول صنع رسومات سريعة ودراسة الأقمشة. سيساعدك هذا على التحسن وجعل تصميماتك مميزة.

حزم التكنولوجيا

حزم التكنولوجيا مهمة جدالصنع ملابس السباحة. لديهم كل التفاصيل اللازمة لجعل التصميم الخاص بك. وهذا يشمل الرسومات والأحجام والمواد وكيفية وضعها معًا. حزم التكنولوجيا تعمل مثل دليلمن أجل المصنع. عند استخدام حزمة التكنولوجيا ، وجعل لكمعدد أقل من الأخطاء والعمل بشكل أسرع. تنظر المصانع إلى العبوات التقنية للتحقق من التعليمات وطرح الأسئلة إذا لزم الأمر. هذا يبقي كل شيء يعمل بسلاسة ويوقف التأخير. يستخدم TideLine ملابس السباحة حزم التكنولوجيا للتأكد من ملابس السباحة الخاصة بك تبدو تماما كما تريد.

الحزم التقنية تساعد في كل خطوةصنع ملابس السباحة.

أنها تحافظ على الجودة والأناقة نفسها.

توقف الارتباك بينك وبين المصنع.

المواصفات

مواصفات أخبر الأحجام الدقيقة والأقمشة وكيفية صنع ملابس السباحة الخاصة بك. صنع نمط هو جزء كبيرمن هذه الخطوة. تأكد من أن ملابس السباحة الخاصة بك تناسب بشكل جيد وتبدو لطيفة. يستخدم صانعو الأنماط حزمة التكنولوجيا الخاصة بك لإنشاء أنماط تتوافق مع أفكارك. إنهم يفحصون أشياء مثل أين تذهب الأشرطة ، ومدى ارتفاع الأرجل ، ومقدار الدعم هناك. جيدةصنع نمطتوقف المشاكل مثل سقوط الأشرطة أو نوبة سيئة. اختبارات ملابس السباحة TideLine عينات للتحقق من الملاءمة والجودة قبل اتخاذ الكثير. تحصل على عينات في غضون 7 إلى 10 أيام ، وهو أسرع بكثير من معظم الشركات. هذا يساعدك على بدء البيع عاجلاً والحفاظ على الاتجاهات الجديدة.

اعثر على الشركة المُصنِّعة المناسبة

اختيار أفضل شركة مصنعة لملابس السباحة المخصصة أمر مهم للغاية. تحتاج إلى شريك يحصل على أفكارك ويساعدك من البداية إلى النهاية. ملابس سباحة TideLine خاصة لأنها تتيح لك طلب كميات صغيرة. لديهم مديري المشاريع الذين يساعدونكم. أنها توفر العديد من خدمات صنع ملابس السباحة. سيوضح لك هذا الجزء كيفية العثور على المواد واختيار الشركة المصنعةطلب عينات.

مواد توريد

عليك اختيار الأقمشة الجيدة لملابس السباحة الخاصة بك. المواد التي تختارها تغير مدى راحة وقوة ملابس السباحة الخاصة بك. كما أنها مهمة للكوكب. تستخدم العديد من العلامات التجارية البوليستر والنايلون المعاد تدويره. يستخدمون الأقمشة التقنية لملابس سباحة أفضل ولمساعدة الأرض. شهادات مثل معيار Oeko-Tex 100 ، GOTS ، والتجارة العادلةيعني أن المواد آمنة للناس والطبيعة. هذه الشهادات تعني أيضًا استخدام كميات أقل من المياه والطاقة.

هنا هو الجدول الذي يظهرمواد ملابس السباحة الشعبيةكيف يساعد هذا الكوكب:

نوع المادة | الخصائص | جانب الاستدامة |

|---|---|---|

بولي أميد (نايلون) | تمتد ، تحافظ على الشكل ، تدوم طويلاً | يمكن صنعه من النايلون المعاد تدويره |

بوليستر | يجف بسرعة وقوية | البوليستر المعاد تدويره يأتي من الزجاجات البلاستيكية |

الإيلاستين (سبانديكس) | ينحني بسهولة ، ويوفر الدعم | في كثير من الأحيان مختلطة مع الألياف المعاد تدويرها |

الأقمشة الفنية | يعمل بشكل جيد ، الحياكة سلس | تستخدم الأصباغ الصديقية للبيئة والطاقة المتجددة |

الشهادات | Oeko-Tex, GOTS, تجارة عادلة | جيد للناس والبيئة. |

ملابس سباحة للرجال TideLine تستخدم الليكرا والسبانديكس والبوليستر. هذه تعطي التمدد والحماية ضد الكلور. خط ملابس السباحة المستدام الخاص بهم يستخدم الألياف البلاستيكية المعاد تدويرها والقطن العضوي. هذا يدل على أنهم يهتمون بالأزياء الخضراء. يمكنك اختيار المواد والشركات المصنعة التي تتوافق مع نمط علامتك التجارية واحتياجاتها.

نصيحة: ابحث دائمًا عن الشهادات عند اختيار الأقمشة. هذا يساعدك على كسب ثقة العملاء الذين يهتمون بالكوكب.

اختيار الشركة المصنعة

تحتاج إلىاختيار الشركة المصنعة التي تناسب أهداف علامتك التجارية. أولاً ، حدد ما تحتاجه ، مثل السوق وأنواع المنتجات والمال لصنع ملابس السباحة. ابحث عن الشركات المصنعة التي تصنع دفعات صغيرة أو كبيرة. ملابس سباحة TideLine تتيح لكطلب عدد قليل من 30 قطعة. هذا رائع للعلامات التجارية الجديدة. يمكنك مزج الأنماط أو الألوان لتلبية الحد الأدنى للطلب. هذا يقلل من المخاطر ويتيح لك تجربة المزيد من التصاميم.

عند التحقق من الشركة المصنعة ، فكر في هذه الأشياء:

هل يمكنهم الحصول على المبلغ الذي تريده ؟

هل لديهم الكثير من الأقمشة وطرق التخصيص ؟

هل موادها آمنة وجيدة للكوكب ؟

ما هو الحد الأدنى للطلب وكم يستغرق ؟

هل يعاملون العمال بإنصاف ؟

هل تتحدث بوضوح وتساعدك أثناء العملية ؟

هل يمكنهم صنع أحجام للجميع وميزات خاصة ؟

هنا قائمة مرجعية لمساعدتك على مقارنة الشركات المصنعة:

الحد الأدنى من الطلب المرن وخيارات الخلط

العديد من خيارات النسيج والمواد

شهادات السلامة والكوكب

حديث واضح ومديري مشاريع مفيدة

تاريخ جيد في صنع ملابس السباحة

يساعدك مديرو مشاريع ملابس السباحة TideLine في كل خطوة. إنهم يتأكدون من أن ملابس السباحة تناسب احتياجاتك وميزانيتك. إنهم يعملون مع العلامات التجارية الجديدة والقديمة ، لذلك تحصل على مساعدة جيدة.

طلب عينات

قبل أن تصنع الكثير من ملابس السباحة ، اسأل دائمًا عن العينات. تتيح لك العينات التحقق من القماش والخياكة ومدى صنعها. تساعدك هذه الخطوة على تجنب الأخطاء والتأكد من أن ملابس السباحة الخاصة بك على ما يرام.

إليك بعض النصائح لطلب العينات وفحصها:

اطلب قطع اختبار للتحقق من القماش ، والملاءمة ، وكيفية صنعها.

جرب العينات في الحياة الواقعية ، كما هو الحال في الكلور أو المياه المالحة.

مقارنة التصاميم المختلفة لمعرفة الأفضل.

قراءة التعليقات من العلامات التجارية الأخرى وزيارة المصنع إذا كنت تستطيع.

اسأل عن الحد الأدنى من الطلبات ، وكم يستغرق ذلك ، وطرق التخصيص.

اختر الشركات المصنعة التي صنعت ملابس السباحة من قبل وقم بعمل جيد.

ملابس السباحة TideLine تعطيك عينات سريعة ، عادة في 7 إلى 10 أيام. هذا يساعدك على الانتقال من الفكرة إلى البيع بسرعة. تتأكد عمليات فحص الجودة من أن كل عينة جيدة قبل طلب المزيد.

ملاحظة: العينات ليست فقط حول كيف تبدو. تحتاج إلى اختبار الراحة والقوة والملاءمة حتى تكون ملابس السباحة الخاصة بك أفضل من غيرها.

من خلال القيام بهذه الخطوات ، يمكنك العثور على أفضل شركة مصنعة ، والحصول على المواد المناسبة ، وإعداد أعمال ملابس السباحة الخاصة بك لتحقيق النجاح. فكر دائمًا في ميزانيتك واعمل عن كثب مع الشركة المصنعة للوصول إلى أهدافك.

أخذ العينات والنماذج الأولية

إنشاء عينة

عليك أن تبدأعملية أخذ العينات والنماذج الأوليةعن طريق تحويل تصميمك إلى عينة ملابس سباحة حقيقية. تساعدك هذه الخطوة على رؤية كيف تبدو أفكارك وتشعر بها. ملابس سباحة TideLine تجعل هذه الخطوة سريعة. يمكنك الحصول على العينة الأولى في أقل من 7 إلى 10 أيام. يستخدم الفريق حزمة التكنولوجيا الخاصة بك ، والتي تحتوي على جميع الرسومات والقياسات وخيارات النسيج. يقومون بإنشاء نموذج أولي حتى تتمكن من التحقق من الملاءمة والنمط قبل الانتقال إلى الإنتاج الكامل. يجب أن تتوقعالعينة الأولى التي تحتاج إلى تغييرات. قد لا يكون مثاليًا ، ولكنه يمنحك فكرة واضحة عما ستبدو عليه ملابس السباحة الخاصة بك.

ها هيالخطوات الرئيسية في إنشاء العينات:

اصنع تصميمك واختر المواد.

إنشاء نمط يعتمد على تصميمك.

بناء النموذج الأول من أجل الملاءمة والأناقة.

راجع العينة ولاحظ أي تغييرات.

ملابس سباحة TideLine تستخدمنظام مراقبة الجودة الصارمةخلال هذه المرحلة. تمر كل عينة بفحوصات للتطير والنسيج والحلي. هذا يضمن أن ملابس السباحة الخاصة بك تلبي معايير الجودة العالية.

اختبار صالح

اختبار صالحجزء أساسي من صنع ملابس السباحة عالية الجودة. حاول أنت أو النموذج المناسب أن تجرب العينة لترى كيف تشعر بها وتتحرك. ملابس سباحة TideLine تختبر ملابس السباحة في الماء للتحقق من وقت التمدد والراحة والتجفيف. يبحث الفريق عن مشاكل مثل الضيق أو الرخاوة أو عدم الراحة. كما أنهم يتحققون مما إذا كانت ملابس السباحة تحافظ على شكلها بعد السباحة. يجب مقارنة العينة مع الحزمة التقنية الخاصة بك وتدوين الملاحظات حول ما يحتاج إلى إصلاح. تساعدك هذه الخطوة على تجنب المشكلات في الإنتاج الضخم.

جرب ملابس السباحة على أنواع الجسم المختلفة.

اختبار في ظروف السباحة الحقيقية.

تحقق من طبقات وأشرطة وأجهزة القوة.

صقل

بعداختبار صالح، يمكنك الانتقال إلىصقلالمرحلة. يمكنك تقديم ملاحظات حول العينة ، وإجراء الشركة المصنعة تغييرات. قد تستغرق هذه الخطوة بضع جولات. في كل مرة ، تحصل على عينة جديدة مع تحسينات. ملابس سباحة TideLine تدعمك بإجراء تعديلات سريعة والتواصل الواضح. يركز الفريق على كل من الراحة والأناقة. يستخدمون تعليقاتك لضبط الأنماط والأقمشة والتفاصيل. تضمن هذه العملية استعداد ملابس السباحة الخاصة بك للتصنيع على نطاق واسع وتفي بمعايير الجودة لعلامتك التجارية.

نصيحة: تحقق دائمًا من كل التفاصيل قبل الموافقة على العينة النهائية. صقل جيد يؤدي إلى ملابس السباحة عالية الجودة التي تبرز في السوق.

عملية إنتاج ملابس السباحة

إنهاء الطلب

بعد أن تقول نعم للعينات الخاصة بك ، تنتقل إلى وضع اللمسات الأخيرة على الطلب. هذه الخطوة تجعل من كل التفاصيل الخاصة بكعملية إنتاج ملابس السباحةصحيح. تنظر إلى حزم التكنولوجيا الخاصة بك ، ومختارات القماش ، والأحجام ، وكم تريد. يمكنك أيضًا التحقق من ميزانيتك لصنع ملابس السباحة. يمنحك ملابس السباحة TideLine مدير مشروع لمساعدتك في التحقق من كل جزء. هذه المساعدة تبقيك من ارتكاب الأخطاء وتساعدك على البقاء منظمًا.

تحتاج إلى التحقق من هذه الأشياء:

آخر خيارات التصميم والألوان

أرقام حجم لكل نمط

مختارات قماش وكسوة

العلامة التجارية المخصصة أو التعبئة والتغليف التي تريدها

قواعد الدفع ومكان إرسال طلبك

عند الانتهاء من طلبك ، تضع الشركة المصنعة طلبكملابس سباحةفي خط لصنع. هذه الخطوة توفر مكانك وتحدد الوقت للخطوات التالية.

نصيحة: اكتب دائمًا تفاصيل طلبك. هذا يساعدك على حل المشاكل بسرعة إذا حدثت.

تخطيط الجدول الزمني

يجب أن تخطط كم من الوقت جعل الخاص بكملابس سباحةسوف تأخذ. هذا يساعدك على الإطلاق في الوقت المحدد. صنعملابس سباحةمن أجل التسليم عادة ما يستغرق حواليمن 4 إلى 4.5 أسابيع. هذه المرة تغطي القطع والخياطة والشحن. إذا كنت في حاجة إليها عاجلا ، يمكن لبعض الشركات جعلها أسرع. ملابس سباحة تيديلين معروفة بالعمل السريع ، خاصة للطلبات الصغيرة.

هنا هو جدول زمني عادي للعرفملابس سباحة:

خطوة | الوقت المقدر |

|---|---|

أخذ العينات والمراجعات | |

قطع وخياطة سائبة | 3-10 أيام |

مراقبة الجودة& إنهاء | 2-5 أيام |

الشحن | 3-5 أيام عمل |

المجموع | 4-4.5 أسابيع |

فكر دائمًا في المدة التي تجعلملابس سباحةسوف تأخذ عند اختيار تاريخ الإطلاق الخاص بك. خطط للتأخير ، خاصة عندما يكون مشغولاً. التحدث كثيرًا مع الشركة المصنعة يساعدك على تجنب المفاجآت. ملابس سباحة TideLine يمكن أن تجعل أكثرملابس سباحةمع نمو علامتك التجارية ، لذلك لا يتعين عليك الانتظار طويلاً.

ملاحظة: صنعملابس سباحةبالقرب من المنزل يمكن أن يعني الشحن الأسرع والتحدث الأسهل. هذا يمكن أن يساعدك على تلبية المواعيد النهائية الضيقة.

مراقبة الجودة

مراقبة الجودة مهمة جدا فيعملية تصنيع ملابس السباحة. تريد أن تكون كل قطعة عالية الجودة. TideLine ملابس السباحة التحقق من الجودة في كل خطوة. هذا يجعل التأكد الخاص بكملابس سباحةيبدو جيدًا ، يناسب جيدًا ، ويستمر لفترة طويلة.

خطوات مراقبة الجودة العادية هي:

فحص النسيج للحصول على جودة وقوة جيدة

اختبار الملاءمة والراحة على أشخاص مختلفين

التأكد من أن الألوان لا تتلاشى في الماء أو الشمس

تبحث في طبقات لمعرفة ما إذا كانت قوية وحتى

القيام بالشيكات للعثور على المشاكل في وقت مبكر

تعليم العاملين القيام بعمل أفضل وارتكبت أخطاء أقل

يجب عليك أيضًا التحقق من بعض القطع بنفسك. انظر إلى عينات عشوائية من كل دفعة. راقب الخيوط الفضفاضة ، أو الطبقات غير الزوجية ، أو الألوان التي لا تتطابق. إذا كنت ترى مشكلة ، أخبر الشركة المصنعة الخاصة بك على الفور. الشركات الجيدة مثل ملابس السباحة TideLine ستساعدك على حل المشكلات بسرعة.

إليك قائمة مراجعة لمراقبة الجودة:

النسيج ناعم وليس لديه مشاكل

الألوان هي نفس العينات الخاصة بك

الأحجام صحيحة وتطابق ما تريد

طبقات قوية وحتى

ميزات خاصة (مثل مقاومة الماء) تعمل بشكل صحيح

نصيحة: احتفظ بالملاحظات حول أي مشاكل في الجودة. هذا يساعدك على تقديم طلبات أفضل في المرة القادمة والحفاظ على معاييرك عالية.

الـعملية إنتاج ملابس السباحةفي TideLine ملابس السباحة يستخدم صنع ذكي ، وفحص الجودة القوي ، والدعم الكامل. تحصل على نتائج جيدة إذا طلبتم عدد قليل أو الكثير. هذا يساعد علامتك التجارية على كسب الثقة والنمو في السوق.

التعبئة والتغليف والشحن

الإعدادية المنتج

تريد أن تبدو ملابس السباحة الخاصة بك جميلة عندما تصل. التغليف الجيد يحافظ على أمان منتجاتك ويظهر علامتك التجارية. ملابس سباحة تيديلين تمنحك العديد من الطرق لتعبئة ملابس السباحة الخاصة بك. يمكنك اختيارصناديق أدراج ، صناديق إغلاق مغناطيسية ، صناديق من قطعتين ، صناديق عرض النوافذ ، أو صناديق الوسائد. كل نمط مربع يساعد على حماية وإظهار ملابس السباحة الخاصة بك.

نمط التعبئة والتغليف | الوصف والفوائد |

|---|---|

صناديق بدرج | مزخرفة ، منزلقات مفتوحة ، جيدة لملابس السباحة الخاصة |

صناديق إغلاق مغناطيسية | تبدو رائعة ، تغلق بإحكام |

صناديق من قطعتين | قوي ، كلاسيكي ، سهل الفتح |

صناديق عرض النافذة | يتيح للناس رؤية ملابس السباحة ، جيدة للمتاجر |

صناديق وسائد | صغيرة ، أنيقة ، تناسب العناصر الصغيرة |

يمكنك اختيار طلاءات مثل اللمعان أو غير اللامع أو مطفي أو بلمسة ناعمة. هذه تجعل صناديقك تشعر بأنها مميزة. مواد صديقة للمنتجات مثل ورق الكرافت أو الورق المقوى القابل لإعادة التدويرمساعدة الكوكب. يمكنك طباعة شعارك وألوانك لجعل عبواتك فريدة من نوعها.

نصيحة: استخدم الإدخالات أو الأقسام الصغيرة للحفاظ على أمان كل ملابس السباحة أثناء الشحن.

اللوجستيات

شحن ملابس السباحة الخاصة بك بأمان وبسرعة يهم كثيرا. تحتاج إلى اختيار شروط الشحن التي تعمل من أجلك. إذا كنت تريد التعامل مع كل شيء ، فاختر DDP. تقوم الشركة المصنعة بجميع خطوات الشحن. إذا كنت تريد المزيد من التحكم ، استخدم فوب أو EXW. يمكنك القيام ببعض أو كل خطوات الشحن. الشحن الجوي جيد للطلبات السريعة أو الصغيرة. الشحن البحري أفضل للشحنات الكبيرة ولكنه يستغرق وقتًا أطول.

الحصول على أوراق جاهزة مثل الفواتير وقوائم التعبئة وشهادات الجمارك.

خطة للضرائب والرسوم في كل بلد.

العمل مع شركاء شحن جيدين لتجنب التأخير.

تمنحك ملابس السباحة TideLine أفكارًا للتعبئة وتساعدك في العثور على شاحنين موثوق بهم. هذا يجعل الشحن أسهل ، خاصة إذا كنت جديدًا في إرسال المنتجات إلى الخارج.

التوزيع

إن العناية بالمخزون والتسليمات تحافظ على عملك بشكل جيد. تستخدم العلامات التجارية الكبرى التنبؤ بالطلب للتخطيط للأوقات المزدحمة. يمكنك استخدام التتبع في الوقت الفعلي لمشاهدة المخزون والشحنات الخاصة بك. ملابس سباحة TideLine تساعد العلامات التجارية الجديدة والقديمة مع أحجام طلب مرنة وخدمة سريعة.

تحدث بوضوح مع الموردين لتغيير الطلبات بسرعة.

إضافة المزيد من المخزون قبل الأوقات المزدحمة وخفضه بعد لتجنب الكثير.

أتمتة عمليات الإرجاع وتتبع الشحن لمساعدة العملاء.

ملاحظة: تساعدك الإدارة الجيدة للمخزون على تجنب نفاد أو ترك الكثير من ملابس السباحة.

تساعدك تجربة واتصالات TideLine في ملابس السباحة على التسليم في الوقت المحدد والحفاظ على سعادة عملائك.

يمكنك بدء متجر ملابس سباحة عبر الإنترنت إذا اتبعت الخطوات. اختيار الأقمشة مثل البوليستر والنايلون ، أو مزيج من مزيج الاسود. هذه الأقمشة تدوم طويلاً وتشعر بالراحة. عينات اختبار على العديد من أنواع الجسم للتحقق من ملاءمته. انظر إلى الجودة خلال كل جزء من العملية. لا تتسرع في صنع ملابس السباحة الخاصة بك. استخدم دائمًا الحزم التقنية بحيث تكون التعليمات واضحة. ملابس سباحة TideLine تتيح لك طلب كميات صغيرةواحصل على عينات بسرعة. يمكنك أيضًا تخصيص ملابس السباحة الخاصة بك بعدة طرق. يساعدك فريقهم على بناء علامتك التجارية وإرسال ملابس سباحة جيدة في الوقت المحدد.

فاق

كم من الوقت يستغرق صنع ملابس سباحة مخصصة ؟

تستغرق العملية بأكملها حوالي 4 إلى 5 أسابيع. هذه المرة تغطي التصميم وصنع العينات والإنتاج والشحن. ملابس السباحة TideLine يجعل العينات بسرعة. هذا يساعدك على بدء علامتك التجارية في وقت أقرب.

ما هو الحد الأدنى لكمية الطلب لملابس السباحة المخصصة ؟

ملابس سباحة TideLine تتيح لك طلب 30 قطعة فقط للتصاميم الجاهزة للشحن. للتصاميم المخصصة ، تحتاج إلى 50 قطعة على الأقل. هذا يتيح لك تجربة أفكارك دون إنفاق الكثير.

هل يمكنني استخدام مواد غير مخدرة في ملابس السباحة الخاصة بي ؟

نعم! يمكنك اختيار البوليستر المعاد تدويره أو القطن العضوي أو الأقمشة الخضراء الأخرى. ملابس السباحة TideLine لديها العديد من الخيارات- هذه تساعدك على بناء علامة تجارية خضراء وجذب الناس الذين يهتمون بالكوكب.

كيف أتأكد من ملاءمة ملابس السباحة الخاصة بي ؟

يجب عليك اختبار العينات على العديد من أنواع الجسم. تقديم ملاحظات بعد كل تركيب. ملابس سباحة TideLine تساعدك على إصلاح الأنماط وتغيير الأحجام حتى تصبح مناسبة.

ما الدعم الذي تقدمه ملابس السباحة TideLine للعلامات التجارية الجديدة ؟

يمنحك ملابس السباحة TideLine مدير المشروع ، والمساعدة في التصميم ، والمشورة بشأن التعبئة والتغليف. تحصل على المساعدة من فكرتك الأولى إلى شحنتك الأخيرة. هذا يجعل بدء علامة ملابس السباحة الخاصة بك أسهل بكثير.